If you’ve been flicking through the pages of Your Home and Garden, or scrolled our Home Tours online, you’ve likely come across one of Matt Watkin’s designs. Stools, planters, bins, and more, his sculptures combine organic form and household function. The result? Some pretty stunning home décor.

Matt is the brains and talent behind Mount-Maunganui homewares brand Special Studio, a company that is turning junk into treasure. Each of their products is formed from 3D technology from 100% recycled plastic, all of which is locally sourced.

We speak to Matt about the creative and innovative process behind the brand.

Tell us about yourself and how you got started in homeware design.

I’m a self-taught multidisciplinary designer I’ve always been interested in design, whether it be graphic, digital, product, or system design.

It wasn’t so much that I specifically wanted to get into homewares, but rather I wanted to move from niche markets like software to a broader, mass market like homewares. I believe that design thinking can be applied to any product segment. I just really enjoy designing new things.

How did the idea for Special Studio come about?

Special Studio was created from the question, “What is the most efficient way to make something?” The vast majority of products in the New Zealand economy are imported, so the goal was to work with locally sourced waste materials and produce locally.

This required rethinking not just what we were making, but how and with what materials. Special Studio, while on the surface a homeware brand, is actually a production and manufacturing company.

Your range of stools and side tables all have such interesting, organic shapes. What inspires the design of your products?

I tend not to derive inspiration outwardly. My design process is entirely digital and involves starting with basic geometry and manipulating, deforming, twisting, and changing the shape until I settle on something I like. It’s more about how I feel when I see the results. Most of the work I do gets deleted and never meets production. It’s a very iterative and creative process, with the best versions making it through to production.

We’re seeing so many mass-produced homewares in the market today. What made you decide to use 100% recycled plastic?

When trying to answer the efficiency question, I started by finding the best material to use in production. It had to be cheap, easy to form, locally sourced, sustainable, and derived from waste.

Both polymers (plastics) and ceramics were the options that came out on top. I settled on polymers because of their strength and durability and their ability to be recycled. Ceramics, on the other hand, while “natural,” cannot be recycled, are heavy, and require a lot of energy to process, particularly in the firing stage of production.

3D printing is such an exciting tool to use. Have you experienced many challenges with this technology?

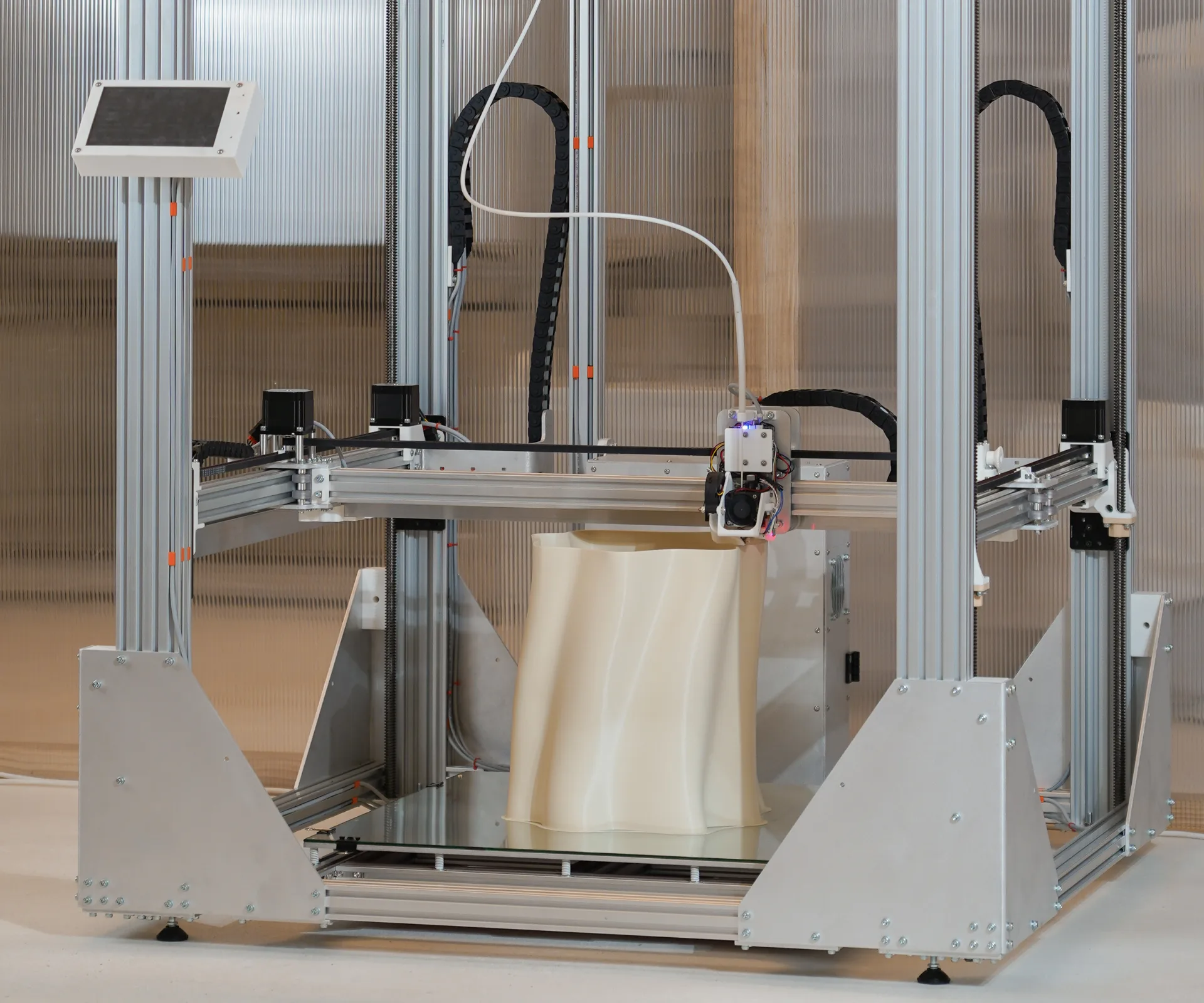

Challenging would be an understatement. We design and build our machines due to the multitude of issues with off-the-shelf 3D printers. A few years back, we decided to design and build a machine from scratch so that we could take control of the production process and eliminate variables we couldn’t otherwise control. We’ve only just settled on the final design and are happy with the results.

However successful prints are hard to reproduce, and we still have failures from time to time. Due to this, we have invested in the ability to recycle our own materials in-house and work with local suppliers who can reprocess material in bulk when needed. This sets us apart from many other 3D printing studios, most of whom do not have this capability.

This means our production system is truly circular, allowing us to recycle our products over and over again. Most brands do not have a plan for what happens once their products are no longer needed or fit for purpose. At Special Studio, we have that covered.

Do you have any new products you’re dreaming up? What’s next for Special Studio?

We have a range of new products in the works, including mirrors, lamps, larger chairs, and settings, and more. I think people will be surprised at what’s coming and how broad our range will be.

That’s one of the great things about actually making the things we design and sell—we have so much control over the process that we can pivot quickly and expand into new product segments with more agility.

Related articles:

- 5 Aotearoa ceramists making waves in the art world

- How local photographers Alex and Sony turn wanderlust into art

- Scents of place: a peek at Kristine Crabb’s tropical paradise